Trending searches

Popular collections

Popular products

Cart ($0)

Cart ($0)

Longer B1 is a Laser Engraver characterized by an output of 20w or 30w or 40w, depending on the user's preference, and a large working area of 450 x 440 mm. In this way, each customer can meet their own needs, both in terms of power and size.

However, in order for the entire work area to be fully usable, the surface on which Longer B1 has been placed must be totally flat and level. This, in fact, is very important as the laser module must always be at the same distance from the work surface, so as to always maintain the right focus distance. If the plane is irregular, there may be some points where the focus distance is correct, some points where the distance is too short, and some points where the distance is too great; Obviously, in places where the distance is too large or too small, it happens that the focus is lacking, and therefore the laser engraving inevitably loses quality at these points.

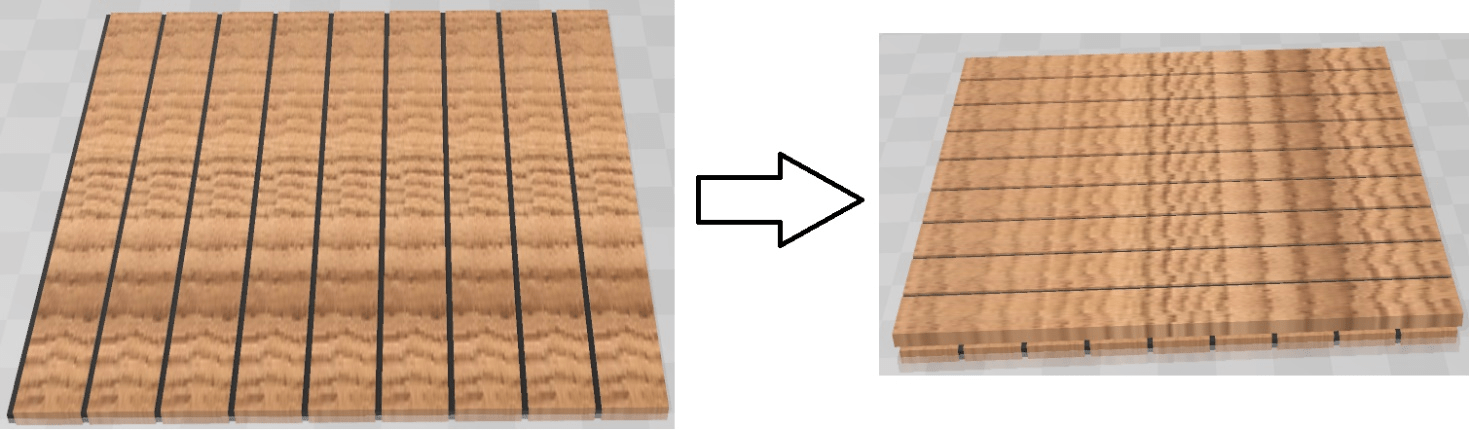

To effectively solve the problem, you can try to grind the work surface, especially when the worktop has only small irregularities, in the order of a few millimeters. To rectify the worktop, you can proceed in this way: using wooden boards (taking care to choose them perfectly flat and without curves) you proceed to create a first layer to be screwed onto the worktop. Then, again using other wooden boards, a new layer is created, to be screwed onto the previous layer in the opposite direction.

In this way, each layer tends to reduce the curvature error of the workplane, and the more layers are added, the greater the grinding of the workplane. Usually, for small irregularities, two rectified layers are sufficient to make the irregularities of the worktop negligible. At the end of the procedure, the surface will allow the laser module to always have the same distance at every point of its engraving area, and therefore the entire area of 450 x 440 mm can be used correctly without losing quality due to poor focusing.

Finally, to protect the newly created worktop from accidental damage caused by the laser beam, as well as improve the engraving and cutting quality, you can get the Longer Honeycomb Working Table. Its structure is similar to that of a honeycomb, and it is made of aluminum and steel. Thanks to the presence of regular holes, this surface allows the laser to pass through the machining and thus cut the material more easily, while also leaving gaps for gases and particles produced during the cutting process to escape. In addition, the honeycomb minimizes contact between the material to be cut and the worktop, reducing the risk of damage to the worktop itself; In addition, the honeycomb structure provides solid support to the material being processed, preventing the surface of the material from bending or deforming during laser cutting. Longer Honeycomb Working Table, available in various sizes, is certainly an essential accessory to complete the Longer B1 worktop in the best possible way.

!