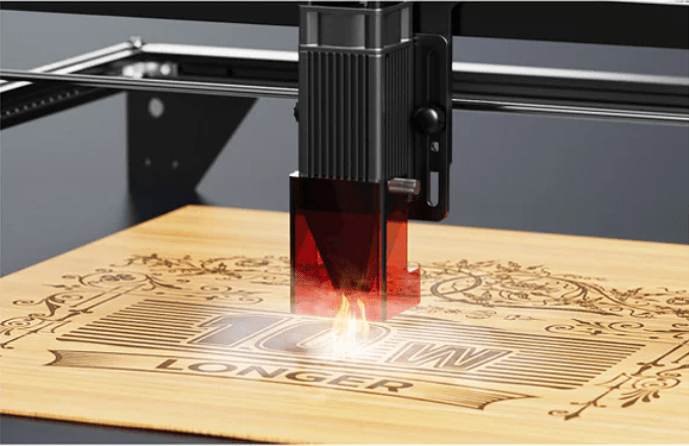

Wooden materials are indeed popular for laser engraving due to their versatility in processing and wide range of applications in various industries. Whether engraving intricate designs on wooden signs, engraving personalized messages on wooden gifts, or creating custom signage for business, wood is ideal for laser engraving projects. Its natural texture and warm texture add unique beauty to carved products and are favored by consumers. However, due to the immaturity of the user's engraving technology, there are often consequences such as excessive material consumption and unsatisfactory engraving effects. Therefore, achieving precise engraving on wooden materials requires some skills and precautions.

Tips for Engraving Wooden Materials with Laser Engraving Machine

Here are some practical tips to help creator achieve precise laser engraving of wood materials:

-

Wood selection: Different types of wood have different densities and textures, which directly affect the effect of laser engraving. Therefore, you need to consider its texture, color and grain when choosing wood to ensure the final carving is as intended. Typically, solid, clear-grained woods are better suited for laser engraving because they provide clearer, more precise engraving results. In addition to common woods such as oak, cherry, and maple, you can also try some special materials, such as birch, walnut, etc., to increase the diversity and personalization of your works.

-

Adjust laser parameters: Laser power, speed, frequency and other parameter settings have a vital impact on the engraving effect. Depending on the type and thickness of the wood material selected, these parameters must be adjusted appropriately to ensure accuracy and consistency in engraving. Generally speaking, for harder wood, higher power and speed are needed to ensure sufficient scoring depth and efficient scoring speed. The longer laser B1 series machine has a power of 20W-40W, uses an upgraded 32-bit motherboard, and has an engraving speed of up to 36000mm/min. It can engrave harder materials; for softer wood, lower parameters are required to avoid damage to the wood surface. Excessive charring or heat damage. Several models in the Longer Ray5 series range from 5-20W and are better suited for engraving and cutting softer woods.

-

Pre-treatment: Proper pre-treatment of the wood material before laser engraving can improve the engraving effect. This involves sanding the surface of the wood to remove any unevenness or wood fibers that may be present, ensuring a smooth surface. In addition, applying appropriate carving primer is also an effective way to improve the effect of engraving. It can enhance the smoothness and contrast of the wood, making the carving pattern clearer and details more prominent. Through these pre-processing steps, a more ideal foundation can be provided for subsequent laser engraving work, thereby ensuring that the final engraving effect is more satisfactory.

-

Carry out testing and calibration: Before officially engraving, it is recommended to engrave some test samples first. With these test samples, you can calibrate and adjust your machine to ensure engraving accuracy and consistency. When testing, be sure to pay attention to the engraving, including aspects such as clarity, depth, and detail. If any problems are found, make timely adjustments and corrections to the machine to ensure the quality and accuracy of the final engraving result. In addition, test samples can also be used to evaluate the engraving effects under different parameter settings so that the best parameter combination can be selected for formal engraving. This ensures you get a satisfactory engraving finished product and improves work efficiency.

-

Safety Precautions: Be sure to pay attention to safety when using the laser engraving machine. Especially when working with wooden materials, a number of precautions should be taken to ensure safety. First, be sure to wear standard protective glasses and gloves to avoid damage to the skin and eyes caused by laser radiation. Secondly, the work area should be kept well ventilated to reduce the health effects of harmful gases and dust generated during the laser engraving process. In addition, regular cleaning of the laser engraving machine and the surrounding environment to ensure that the equipment is in good working condition is also an important step to ensure safety. By strictly abiding by safe operating procedures, safety risks during the laser engraving process can be effectively reduced and the health and safety of operators can be protected.

The above provides key tips and considerations for achieving precise laser engraving of wood materials. Longer are definitely a good helper for making wooden decorations. So far, it has released two series of machines, the RAY5 and the Laser B1. The RAY5 series engraving machine is equipped with a 0.08*0.08mm compressed laser spot, which focuses more on energy and perfectly combines simplicity and accuracy, making it an ideal choice for beginners entering the world of engraving and cutting. At the same time, the Laser B1 series machines, with engraving speeds up to 36000mm/min, stand out with their powerful functions and cater to the needs of experienced creators who are proficient in engraving and cutting technologies.

Longer brand laser engravers adopt advanced technology and stable performance, which can meet a variety of different engraving needs and provide excellent engraving effects. In addition, the Longer brand provides users with a full range of after-sales service support with a professional attitude, including timely technical support and maintenance guarantees to ensure the smooth progress of the engraving work. Choosing a Longer brand laser engraving machine not only helps to present the creator's creativity, but also improves the user's craftsmanship and achieves better engraving achievements.