Trending searches

Popular collections

Popular products

Chariot ($0)

Chariot ($0)

Introduction

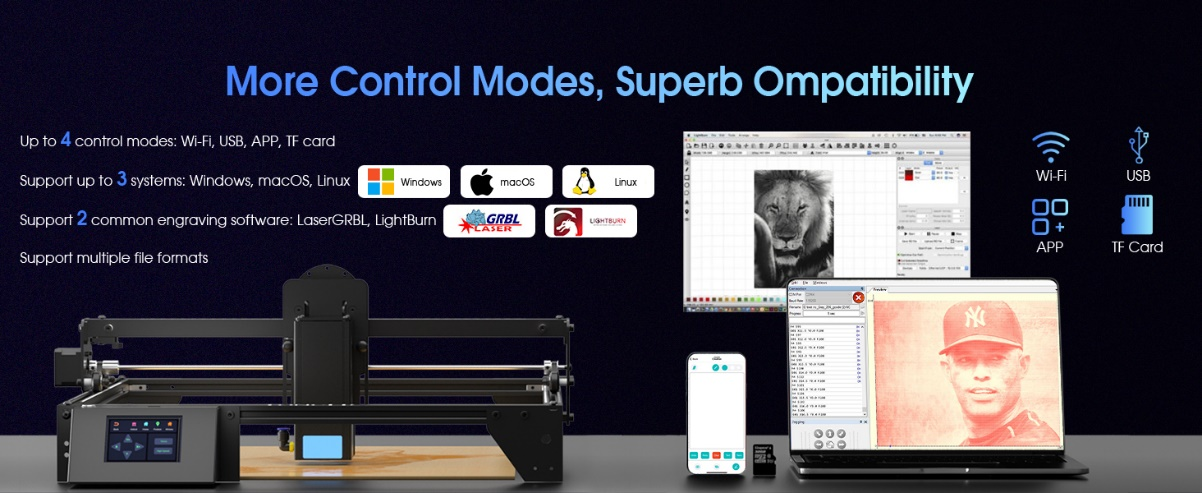

Longer Ray5 20W is a powerful laser engraving machine, but encountering technical challenges with your Ray5 20W Laser Cutter can be frustrating and disruptive to your workflow. Understanding and addressing common issues promptly can help maintain optimal performance and productivity. In this guide, we will explore some of the most frequently encountered problems with the Ray5 20W Laser Cutter and provide effective solutions to resolve them. Whether you're facing issues with cutting precision, engraving depth, or software connectivity, we've got you covered. Let's dive in and troubleshoot these issues together to ensure smooth operation and consistent results with your Ray5 20W Laser Cutter.

Common Laser Cutting Issues and Solutions

Verify Connections:

Confirm secure and proper attachment of all cables and connections.

Regularly update laser cutting software and firmware for bug fixes and enhancements.

Reach out to LONGER's customer service: support@longer.net for assistance with persistent software issues or error messages.

Variations in Cutting Power or Depth:

Ensure correct laser focus settings to prevent uneven cutting depths.

Check for flaws or warping on the material's surface and secure it properly to avoid movement during cutting.

Adjust laser power and speed settings according to the material being cut.

Cut Alignment Problems:

Calibrate the laser cutting equipment accurately to avoid misalignment.

Inspect the X and Y axes for debris or loose parts that may affect cutting alignment.

Position the material correctly on the cutting bed and use alignment markers or guides for precise cuts.

Conclusion

By addressing these common issues effectively, you can ensure smooth operation and achieve high-quality results with your LONGER Laser Cutter. Keep these troubleshooting tips in mind to optimize your cutting process and minimize downtime.

Ray5 20W Laser Cutting Machine offers numerous advantages, making it a preferred choice for various applications. It boasts rapid task completion and high production efficiency, thanks to its quick engraving speeds, enhancing productivity and meeting deadlines effectively. Additionally, its material flexibility allows it to adapt to a wide range of materials, ensuring consistent and precise cutting results regardless of material hardness. Designed for ease of use, the Ray5 20W Laser Cutter offers straightforward operation via computer control, minimizing operational errors and enabling users of all skill levels to achieve professional-grade results with confidence.

In addition to its performance advantages, the Ray5 20W Laser Cutter also boasts environmental benefits. Utilizing laser technology, it minimizes environmental impact by conserving energy, contributing to sustainability and cost savings. Furthermore, its non-contact processing method reduces the risk of faulty products and tool wear, ensuring precision and quality while extending cutting tool lifespan. By eliminating physical contact with the material surface, the Ray5 20W Laser Cutter enhances efficiency, reduces waste, and promotes environmental sustainability.

!